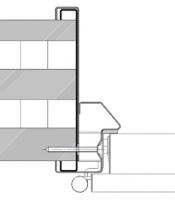

Perfect solution for tight deadline works. Galvanised subframe is to be installed during wall construction which allows to keep right dimension for the door. After door installation the supplement overlaps to the millimeter to the subframe and the door.

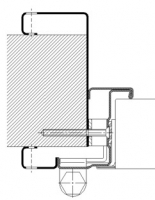

Orders of bi-coloured doors are becoming more and more common. The most common option is coloured external side, matching house metalwork, and the other side in white colour. It has thus been developped a 2-pieces frame, in order to separate both finishes.

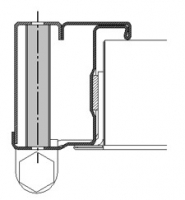

Our solution for panel sandwich installation consists of following items:

-1 L-shaped piece, named counter-frame (if a screwing system is included in the frame), or a supplement piece (a L-shapped piece).

-1 wing piece which serves to extend CS5 frame and to hide imperfections on the panel sandwich edges.

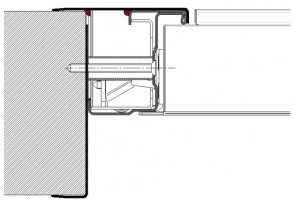

This frame is used in order to wrap the wall giving to the structure a robust appearance. The solidity of the frame is achieved by avoiding any gap between door frame and wrapping frame.

It can be delivered in three ways:

1- Three spare parts, to raise the wall and install on-site.

2- Supplement piece already mounted, but separate from the door

3- Supplement piece already screwed to the CS5 frame door.

Steel frame meant to not to reduce the brick-to-brick opening. It has to be installed on the external side of the wall. Designed for front screwing system.

Solution to improve the isolation of the door frame available in two formats: rock wool or gypsum filling.

Tubular frame with mitred overlap and counter-frame in order to achieve aesthetic and robust doors.